-

Aggregate Treatment

-

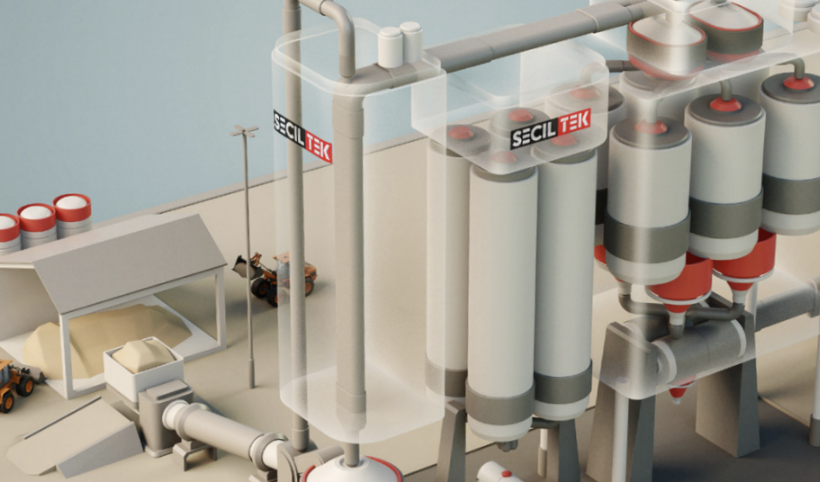

Raw Material Storage in Silos

-

Mixing Tower

-

Bagging and Palletizing

-

Bulk Loading

-

Loading and Shipping

Aggregates are a crucial component included in the production of mortars. To be used, they must undergo a treatment process aimed at improving their characteristics and ensuring the quality, durability, and diversity of the final products.

The aggregates used in Seciltek products go through a process of crushing, drying, and separation into granular fractions until they are ready to be included in the final product.

The raw materials used in the production of various mortars are stored in silos to facilitate their incorporation into the mixing tower more quickly and efficiently.

The mixing tower is equipment used for the efficient preparation and mixing of mortars. These towers are designed to process large quantities of material and ensure a homogeneous mixture ready for bagging.

After the mortars are produced, they are placed in bags and onto pallets, respectively, ready to be shipped.

Some of the mortars produced by Seciltek are distributed in bulk, allowing for the supply of large quantities of product to directly feed silos on construction sites. Among the mortars distributed in bulk are those for masonry, plastering, and screeds.

With the mortars properly packaged, the final part of the process consists of loading and sending them to various sales points located throughout the country.