-

Storage

1.1 Aggregates (sand and gravel)

1.2 Binders (cements and additives)

1.3 Admixtures

1.4 Industrial Water

1.5 Recycled Water

-

Weighing

-

Mixing

3.1 Mixer

3.2 Concrete Truck

-

Dispatch

-

Transportation and Pumping

5.1 Concrete Truck

5.2 Concrete Pump

-

Recycling

The manufacturing process of concrete consists of mixing cement, coarse and fine aggregates (gravel and sand), and water, with or without the incorporation of admixtures and additives. The aggregates and water recovered from the washings resulting from the manufacturing process, as well as from fresh concrete, are completely reused in the production of concrete.

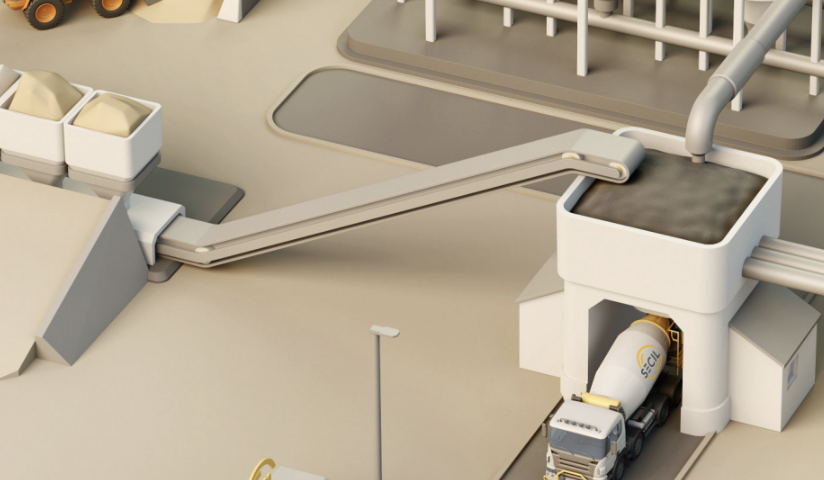

1.1 Aggregates (sand and gravel): Depending on the type of batching plant, the storage of aggregates is done in star or bay configurations, and handling of this material is carried out respectively by dragline or front-end loader

1.2 Binders (cements and additives): These have their own silos and are properly identified and locked with padlocks and/or security systems.

1.3 Admixtures: These have dedicated storage if supplied in bulk. If supplied in containers (IBC) or drums, they are placed near the pumping system.

1.4 Industrial Water and 1.5 Recycled Water: Water for mixing is stored in tanks or reservoirs, properly identified.

The aggregates used in production arrive at the plant via trucks and are stored in appropriate locations (bays or stars) according to their type and granulation. From the storage locations, they are directed to the weighing system and then unloaded into the mixer, where they are mixed with the other constituents.

Cement arrives at the plant in tankers and is stored in suitable silos. Through a screw conveyor, the cement is directed from the silo to the scale, where it is weighed and then unloaded into the mixer, where it will be combined with the aggregates, water, and potentially other additives.

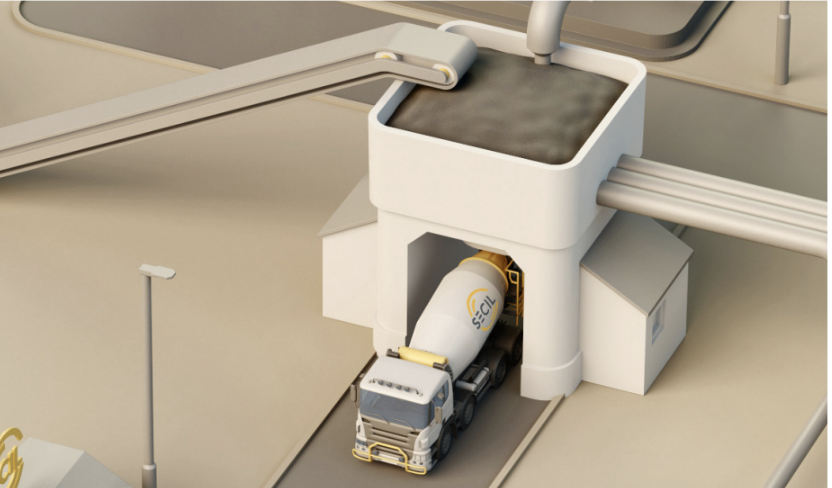

Once all the constituent materials of the concrete are weighed, they are unloaded into the mixer (3.1), where they are blended homogeneously.

Once the mixing process is complete, the concrete is unloaded into concrete trucks (3.2) and transported in a fresh state to the application site.

The concrete truck (5.1) leaves the plant to transport ready-mixed concrete to the customer's site. The concrete pump (5.2) enables the transportation of ready-mixed concrete to the application location.

Washing the equipment in contact with the concrete and recycling concrete waste contributes to the reuse of both water and aggregates.