-

Quarry

-

Crushing

-

Pre-Homogenization

-

Raw Meal Grinding

-

Storage Silos

-

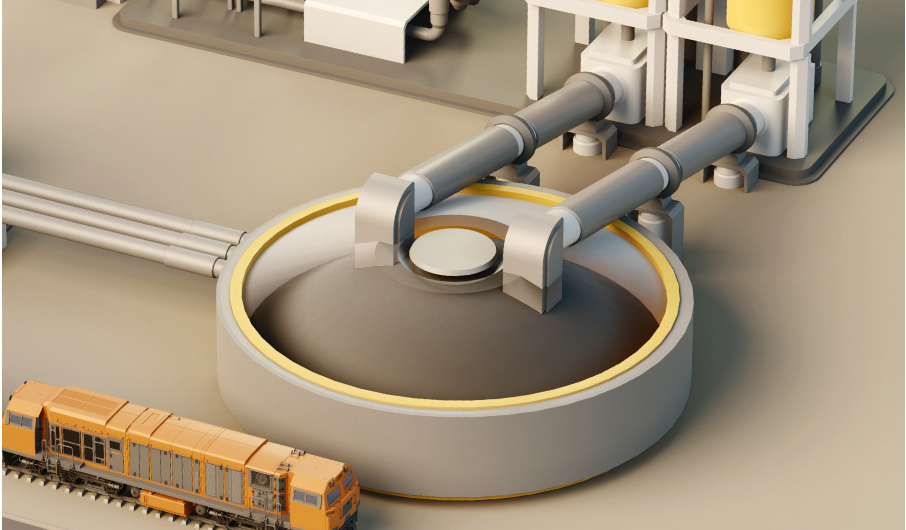

Cyclone Tower

-

Kiln

-

Cement Grinding

-

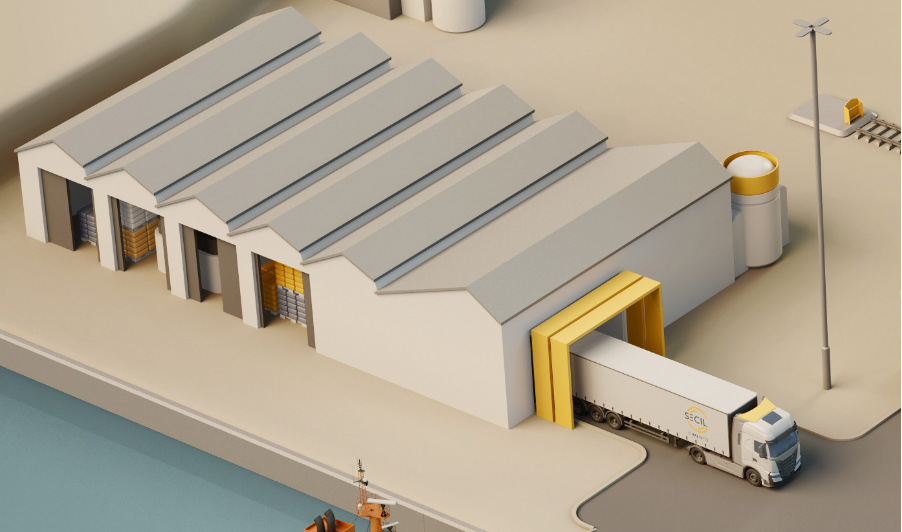

Bagging

-

Dispatch

The main raw materials for the cement manufacturing process are limestone, marl, or clays, which are extracted from our quarries located within the manufacturing perimeter. The extraction is done through open-pit mining, starting from the highest point and working downwards, with blasting carefully applied to minimize vibrations.

The main environmental impacts associated with the extraction, particularly on biodiversity, are minimized through landscape recovery efforts on completed fronts, along with a focus on reducing the use of natural resources by incorporating secondary raw materials.

After extraction, the material comes in blocks that can be as large as about 1 m³, so it must be reduced in size in the crusher to a granulation compatible with transportation, storage, and feeding into the subsequent manufacturing phases.

After crushing, the raw materials go through a storage process that includes a pre-homogenization function to ensure uniformity among the various piles in the warehouse.

The natural raw materials and correction materials (sand and iron oxide) are then dosed, taking into account the quality of the product to be obtained (clinker), an operation that is controlled via process computers.

Once the proportions of the raw materials are defined, they are transported to mills where the so-called “raw meal” is produced. This is a finely ground mixture, in well-defined proportions, of all the natural raw materials and correction materials. Vertical roller mills are used for this grinding.

At this stage, the raw meal is dried using the heat contained in the flue gases from the rotary kilns, which simultaneously transport the raw meal from the mills to the storage silos.

The raw meal is extracted from the storage silos and introduced into the pre-heating system (cyclone tower), where it is heated by the flue gases resulting from the burning of fuels.

The material then enters the kiln, moving along its length due to its rotation and slight incline, continuing to heat up and undergoing the physical-chemical reactions of the clinkerization process at a temperature reaching 1450ºC, resulting in clinker at the end.

Starting from 1450ºC, the cooling of the clinker begins within the kiln and is completed in satellite coolers, where air is introduced in counterflow with the clinker, utilizing this heated air as secondary combustion air. This allows for partial recovery of the thermal content of the clinker, thereby reducing energy consumption in the kilns.

The low emission of particles is ensured through dust removal systems (bag filters and electrostatic precipitators), and the minimization of gas emissions is achieved through automated control systems for kiln operation, both of which are considered Best Available Techniques (BAT).

Cement is produced in horizontal tubular mills with grinding bodies. Clinker, gypsum (a setting regulator for cement), and inert additives are ground in well-defined proportions according to the quality plan, resulting in different types of cement with specific characteristics suitable for their use, which are stored in properly identified silos.

The minimization of electrical energy consumption has been achieved through the adoption of closed-circuit grinding technology with third-generation separators, considered as BAT.

The low emission of particles is ensured by bag filters, also classified as BAT.

Cement is extracted from the silos for bagging. The bagging is done in automated filling lines and palletizing or packaging systems.

Cement is marketed in bulk, extracted from the silos into tank trucks (road), railcars (rail), or ships (via river or sea). It can also be dispatched in bags on wooden pallets or in plastic-wrapped bulk bags.