-

Blasting

1.1 Drilling

1.2 Secondary Fragmentation

-

Loading and Transportation of Rock

-

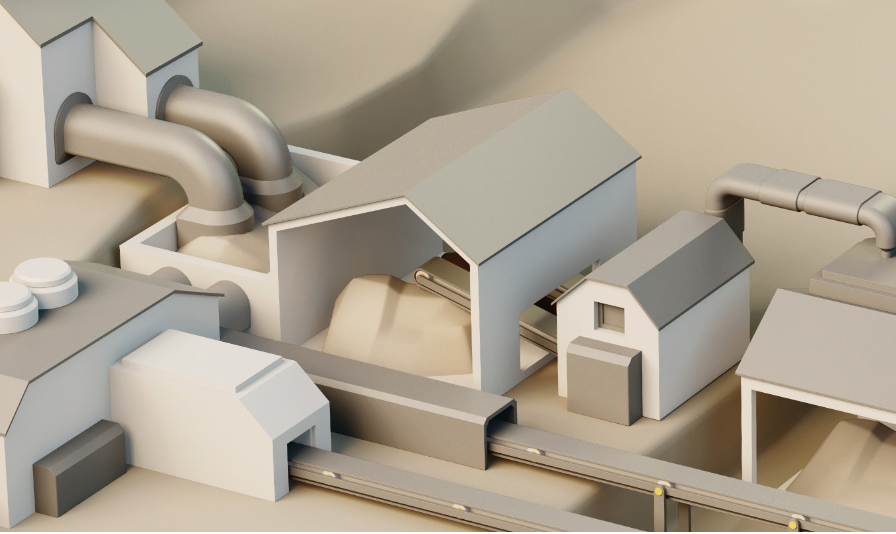

Crushing

-

Loading and Movement of Aggregates

-

Dispatch

Blasting involves the disaggregation of the rock mass through the use of explosives and/or mechanical means.

To prepare the ground for blasting, vegetation and soil covering the mineral resource are removed using a rotary excavator, loader, and/or bulldozer.

1.1 - During the drilling phase, several holes are made as indicated in the drilling diagram. These holes are then loaded with explosives following the firing diagram and detonated to promote the fragmentation of the rock mass

1.2 - Secondary fragmentation may occur, typically using hydraulic hammers, to correct any inadequacies in the initial fragmentation.

The loading and transportation of rocks are carried out using mechanical equipment to remove and transport the disaggregated rock to the crusher.

Loading is done using loaders and/or excavators, while movement is handled by dumpers, which can be articulated or rigid quarry trucks.

Crushing involves a series of fragmentation steps using mechanical means, followed by the separation of the fragmented product into different grain sizes using vibrating screens.

The final product may go through one, two, or three stages of fragmentation. Some processing lines also include a washing unit for the production of washed aggregates.

The storage of the produced aggregates is followed by loading the trucks using manual dispensers from silos or through loaders from stockpiles of material.

After loading the trucks, weighing is done on scales, and corresponding documents for transportation or sale are issued.